Flanged ball valves are critical devices in industrial piping systems that are known for their durability, tight shutoff and ease of operation. In oil and gas, water treatment and chemical processing, a properly installed and well-maintained flanged ball valve can be the difference between successes and failures tens of thousands of dollars in downtime. We guide you through everything you need to know about flanged ball valves; from installation, to maintaining your valves, for reliable long-term use.

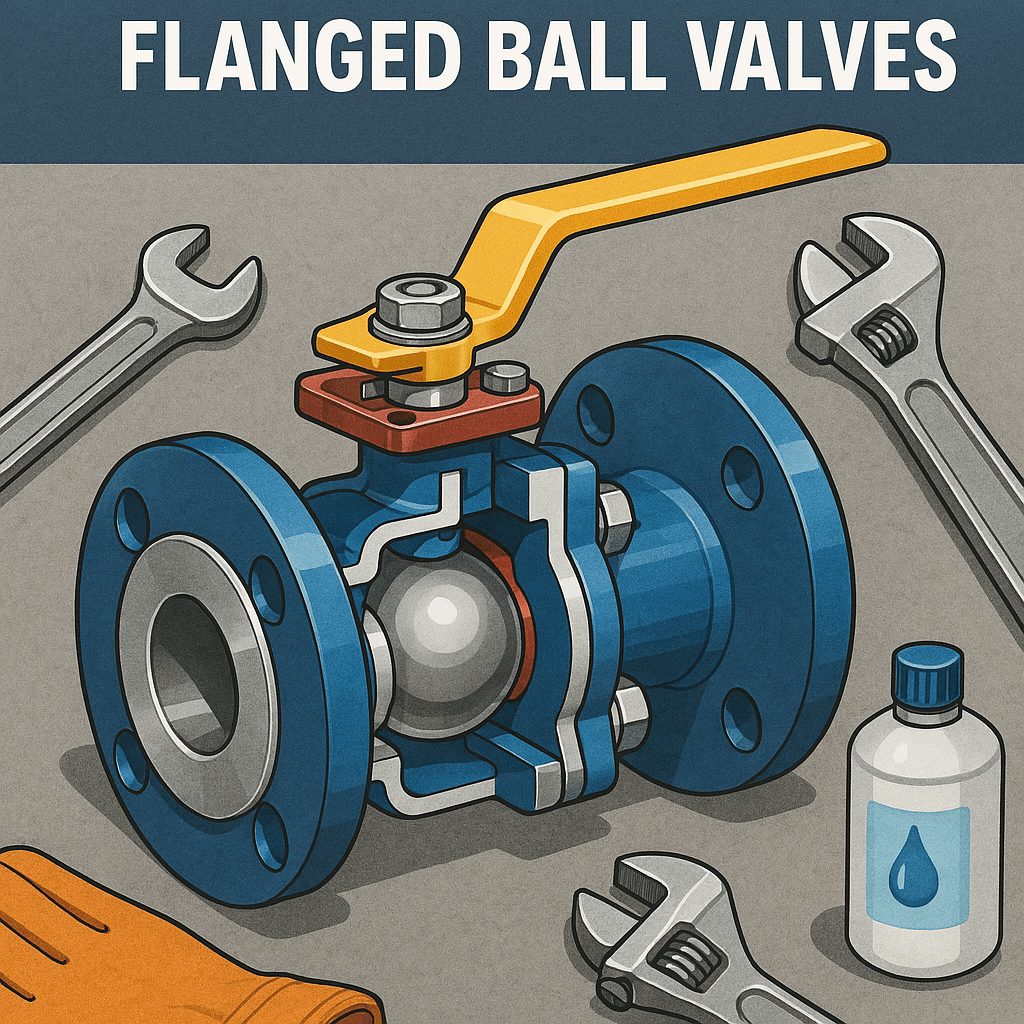

Flanged valve has a simple construction which consists of a rotating ball with a bore that is use to regulate fluid flow. It is called a flanged valve because the connection that attaches the valve to the pipe is a flange with bolt holes in it. A quarter turn is enough to control the flow. These valves are a common feature of pipe systems where leakproof connection is crucial. These valves can handle high pressure and also tolerate high-temperature fluids. The flanged connection also makes the valves easy to replace for maintenance.

Pipe components need to be installed with care because improper installation can make an emergency situation even worse. We advise not making any hasty decisions in installation. Instead, the correct approach is to observe the valve and its components closely to check if there is no damage to flange faces, stem, or ball mechanism. Make sure that the valve bore is clean and free rom any particles of rubbish. The valve should be in partially open position before installation so that the damage risk is minimal while handling during installation.

Checking the specifications of the valve is also a vital step that should be done before installation. Some common specs to check are pressure rating, flange standard and the material construction of the valve.

Before the valve is inserted the pipe should be cleaned thoroughly so that it is free from dust, rust and any particles that will interfere with the flanged valve performance. If the valve becomes contaminated due to debris or rust then it will not fulfill its service life and will get damged early.

• Begin by positioning the flanges of the valve with respect to the piping system. Align the flanges and to ensure airtight sealing use gaskets of a suitable size that fit tightly between the mating flanges. Gasket material should be compatible with the fluid in the pipe and robust enough to withstand the temperature and pressure conditions in the pipe.

• After alignment, comes the step of fastening the flange valve. This is done by insertion of bolts in the flange holes. The bolts should be tightened and inserted in a star pattern so that the pressure is uniformly distributed. This would ensure that the flanges do not become bent due to excessive force. Tightening of the bolt should be first done manually, and then a torque wrench should be used to tighten it further. Take care not to overtighten as it can deform the gasket.

• After installation, release the fluid in the pipes by opening the valve slowly and check for leaks. Make sure the valve operates smoothly by turning the handle or actuator through a full open-close cycle. If resistance is felt or the motion is jerky, stop and investigate. This could indicate internal obstruction or incorrect installation.

One major mistake that is usually done by inexperienced installers is using too much physical force while installing the valve. The valve body should not be used to align the pipe flanges as doing this can cause physical strain on the internal components. Causing them to weaken over time.

Another action not recommended is welding the flanges with the valve without taking the necessary precautionary measures. Improper welding can damage the seals or even warp the ball.

Installing a valve with an improper position is another frequent mistake done by beginners. Most flanged ball valves are bidirectional but in some cases the valves are engineered for flow in a specific direction. Neglecting to see the flow markings on the flanged valves or overlooking the manufacturer’s instructions can result in misaligned valve installation, so make sure to do this before final tightening.

Valve maintenance should be done periodically as it maximizes the service life. The maintenance begins with a most basic step: Inspection. The inspection schedule should be done at fixed intervals which depends on frequency of usage and the nature of fluid in the pipe system. If the pipe system has a high pressure or consists of a corrosive chemical then periodic inspection should be done with more frequency.

Once inspection is done, it is time to implement the maintenance procedure. This involves depressurizing the pipeline and draining fluid from the valve body. Once the fluid is drained, completely rotate the valve to check the ease of movement. If the movement is not smooth and the valve is getting stuck then this signals that there are trash particles clogging the valve. It is also a symptom of seal degradation.

Next, rinse external surfaces and look for signs of rusting. For smooth valve movement, lubrication is important, so cover the stem and seats with lubricants. It is vital to ensure that the lubricant is compatible with the valve material and the nature of the fluid.

Don’t forget to inspect seals and gaskets as these are components that have the most chance of wearing out since they are routinely exposed to harsh conditions. Correct strategy is to look for leakages around the stem or flanges as this means that gaskets have eroded and should be replaced.

Some flange valves consist of an actuator, so checking if this component is working correctly is also vital, and the best way to do this is to inspect the mounting bracket and connection interface. Loose or misaligned actuators can affect the valve’s response time and reliability. Clean electrical or pneumatic lines and verify the actuator's functionality using control systems.

The usual problem with flanged ball valves is leaking. If you have a leaking fluid even though the valve is closed, that means your ball or your seat is damaged or contaminated. To fix this, take the valve apart (following manufacturer's instructions), and take a look at the seat and ball for scratches or pitting. Also, clean or replace the components. If you have difficulty turning the valve, you probably have some buildup in the bore, or around the ball. You could have chemical scaling, debris, or corrosion. You may be able to clean it using the appropriate solvents. But don't scrape or file the ball as that will damage your seal.

A failure of the valve under pressure is associated with improper installation or misaligned flanges, or over-tightening bolts. By inspecting the valve regularly, these conditions should be identified before they become a problem.

Installing flanged ball valves and performing valve maintenance are not complex tasks but require some attention to detail and following best practices. There are a series of steps involved that are interconnected and must be performed in a sequence for correct installation and maintenance. These include correct alignment and torque during installation, regularly cleaning, and routine inspection throughout their lifecycle. Every step is contributing to the effective reliability of the valves over the long term. A bit of set up and care pays off in reduced downtime, reduced leaking, and smoother running systems.

If you are managing a critical process or considering upgrading a system, don’t consider valve installation a problem solved after the fact. Get it right the first time, and then keep it right.

Industries must continually update their operations to achieve the best output. Not staying activ...

READ FULLThe valve system consists of various kinds of components, and actuators are one of them. When it ...

READ FULLValves need support from an electric system that can control them remotely. Not every time and pl...

READ FULL