Valves play a vital role in boosting pipeline system performance and if you are a pipeline system owner who is looking to enhance the efficiency of the system the first thing you should consider for upgrading the system is valve replacement. The butterfly valve and ball valve are two of the most popular flow control choices in piping systems, and at first glance, they might appear to be two differently shaped valves performing the same function. But they are different. Not only are they manufactured differently but they also perform in their own unique way. Selecting the wrong one can lead to overspending, performance issues, or operational headaches. Let's talk about this so that you will have clarity on what valve best suits your needs.

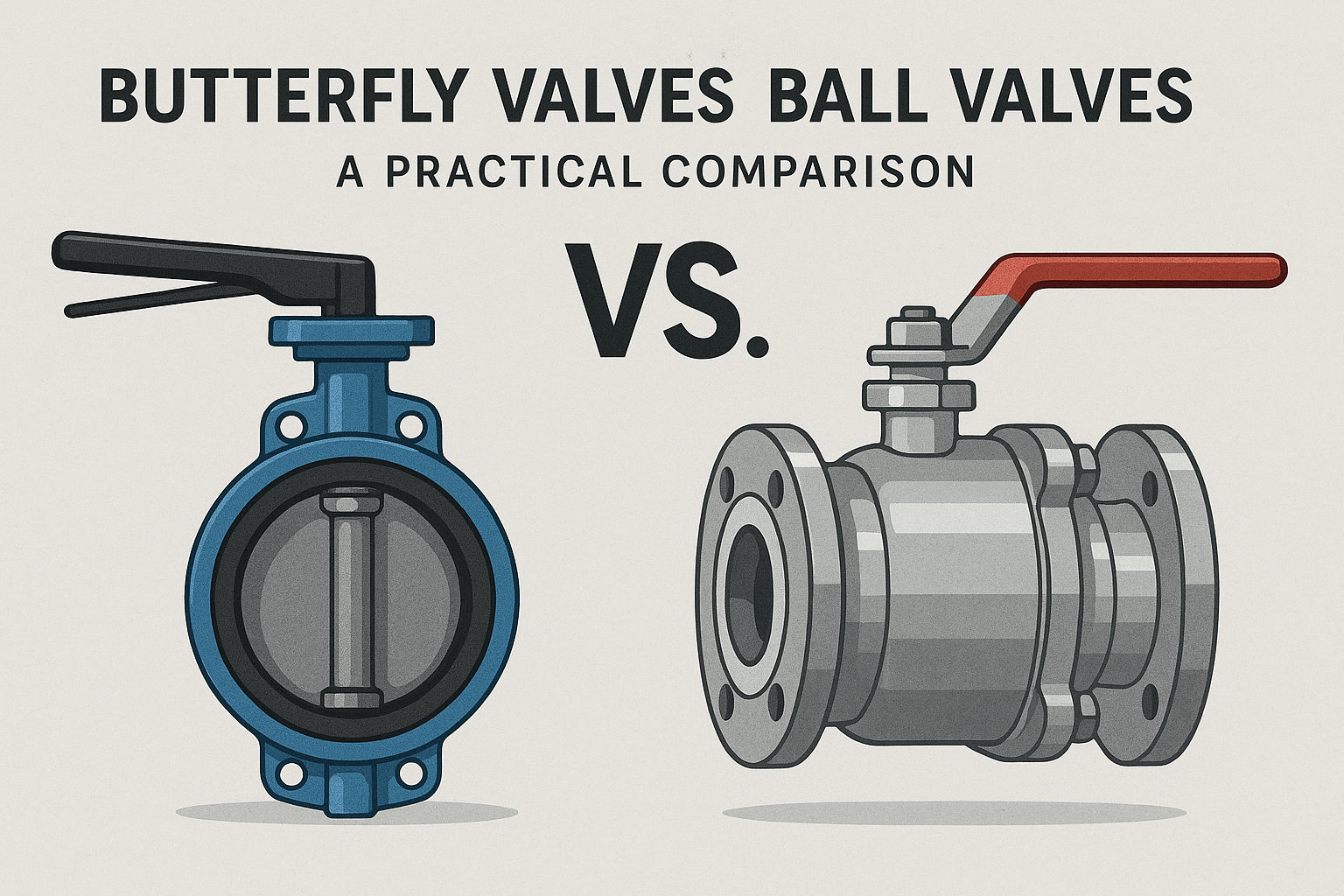

Let’s start with the basics. A ball valve is like the “bouncer” of your piping system. It uses a solid sphere with a hole through the middle: turn it 90 degrees, and the flow is either fully open or fully closed. No halfway drama, no fidgety positions. Ball valves are famous for their tight shut-off. When they’re closed, they’re really closed. On the other hand, a butterfly valve is more like the “door on a hinge.” It has a flat disc that rotates in the flow path. Twist the handle a quarter turn, and the disc swings from blocking the passage to allowing flow. They can do partial openings pretty well, which makes them decent for throttling, but they’re not quite as watertight as ball valves when you need a perfect seal.

Now, let’s talk about size because in the valve world, size does matter. Ball valves start feeling a bit bulky and heavy when you scale up to larger diameters. The sphere inside and the thicker housing mean you’re dealing with more metal, more cost, and more installation muscle. Butterfly valves, though? They’re the lightweights. Even at larger diameters, they stay relatively slim and easy to handle. That’s why you’ll often see them in big water pipelines, HVAC systems, or anywhere size and weight could turn into logistical nightmares.

You'll also need to keep in mind the cost factor. Practically speaking, if you’re working with large pipes and want do not want to burn money, butterfly valves often win. Their design construction uses less material, which translates into lower manufacturing costs and, for you, a smaller hit to the wallet. Ball valves, in contrast, especially in stainless steel or exotic alloys, can get pricey fast, and if you are scaling up then this means spending heavily. That’s why they tend to be the go-to in smaller systems or in industries where precision and sealing are worth paying extra for.

But let’s not just talk price tags, let’s talk performance. The area where ball valve performance really takes the cake is in shut-off conditions. No other valve can compare. Think of situations where even a tiny leak could cause damage like chemical processing, gas lines, and high-pressure water systems. That solid ball design, when paired with good seals, gives you confidence that nothing’s getting through when it’s closed. Butterfly valves, while improving a lot in sealing technology, can still allow a small amount of leakage in some designs, especially under very high pressure. For a fire sprinkler system or municipal water line, that might be acceptable. For handling flammable gas? Not so much.

You might be wondering about flow control. Here’s where it gets interesting. Ball valves are essentially “on/off” specialists. You can technically leave them half open, but that’s not what they’re built for. The high-velocity flow through the partially open ball can cause damage to the valve over time. Butterfly valves, however, love the middle ground. You can adjust them to allow just the amount of flow you need. This makes them a common choice in applications where throttling: the art of adjusting flow precisely is part of daily operations.

Installation and maintenance of both valves tell two very different stories. Ball valves, with their heavier build and threaded or flanged ends, require a bit more effort to install and service, especially in large sizes. Butterfly valves are usually easier to drop into a system because their wafer or lug-style bodies fit neatly between pipe flanges. They’re also easier to maneuver in tight spaces. If you’ve ever tried to install a massive ball valve in a cramped mechanical room, you know exactly why that matters.

Durability-wise, both have their strong points. Ball valves can handle higher pressures and temperatures, which is why they’re common in oil and gas, power generation, and chemical industries. Their solid metal ball can withstand a lot before wearing out. Butterfly valves, while generally not as pressure-resistant, do better in applications with lower pressures and less aggressive media. They can last a long time in water, air, or mild liquid systems, especially when you don’t constantly push them to their limits.

Let’s also touch on the “operator experience,” because whoever’s turning that valve is going to have opinions. Ball valves feel smooth and decisive, a quarter turn and its done. Butterfly valves sometimes require a bit more torque to turn, especially at higher pressures, and their discs in the flow path can add resistance when you’re trying to get that perfect positioning for throttling. In automated systems, both can be fitted with actuators, but butterfly valves are often chosen when space around the valve is limited.

Where do they show up in the real world? In the industrial sectors where the operations are fast-paced and the productivity level needs to be maintained like refineries, chemical plants, compressed gas systems ball valves are the real deal as they provide failproof sealing. They’re also common in smaller residential or commercial setups where reliability is king.

Butterfly valves, on the other hand, are the workhorses of large-scale water distribution, HVAC systems, food processing plants, and marine applications. They handle large volumes without eating up space or budgets.

Now here’s a common mistake: people think they can just swap one for the other in any system. But that is the wrong approach The internal design differences mean they interact with flow differently. A butterfly valve’s disc once installs, comes right in the flow path so even if the valve is fully open a minimal pressure drop always happens. Ball valves, when open, do not hinder the flow at all because the hole in the ball is usually the same size as the pipe. This small detail becomes important in systems where flow efficiency has the highest priority.

When it comes down to it, neither is “better” overall - they’re better for a different work. It’s like comparing sports car with a delivery van. One excels in speed and precision while the other is built for load-bearing and practical driving. You need to be clear about what you want from your pipe system and only then you can make the correct valve choice. Below you will find a comparison table if you are still confused.

|

Feature |

Ball Valve |

Butterfly Valve |

|

Seal Tightness |

Excellent, zero leakage possible |

Good, minor leakage possible in some designs |

|

Size & Weight |

Bulky at larger sizes |

Slim and lightweight |

|

Cost |

Higher, especially in large diameters |

Lower, cost-effective for large pipes |

|

Throttling |

Not ideal |

Very good |

|

Flow Resistance |

Minimal when open |

Slight, due to disc in flow path |

|

Pressure Rating |

Higher |

Moderate |

|

Installation Space |

Needs more space |

Compact |

That way,the next time you find yourself thumbing pages in a valves catalog (or negotiating with your supplier), you will at least be able to give an informed, reasoned decision rather than take a stab at it. It will become clear as to it is better to choose a butterfly valve for space, weight and cost savings or whether you could justify the difference in costs for a ball valve simply for peace of mind. Ultimately, this is the kind of understanding that keeps piping systems functioning better, and prevents you from having the regret of taking a wrong decision.

Industries must continually update their operations to achieve the best output. Not staying activ...

READ FULLThe valve system consists of various kinds of components, and actuators are one of them. When it ...

READ FULLValves need support from an electric system that can control them remotely. Not every time and pl...

READ FULL