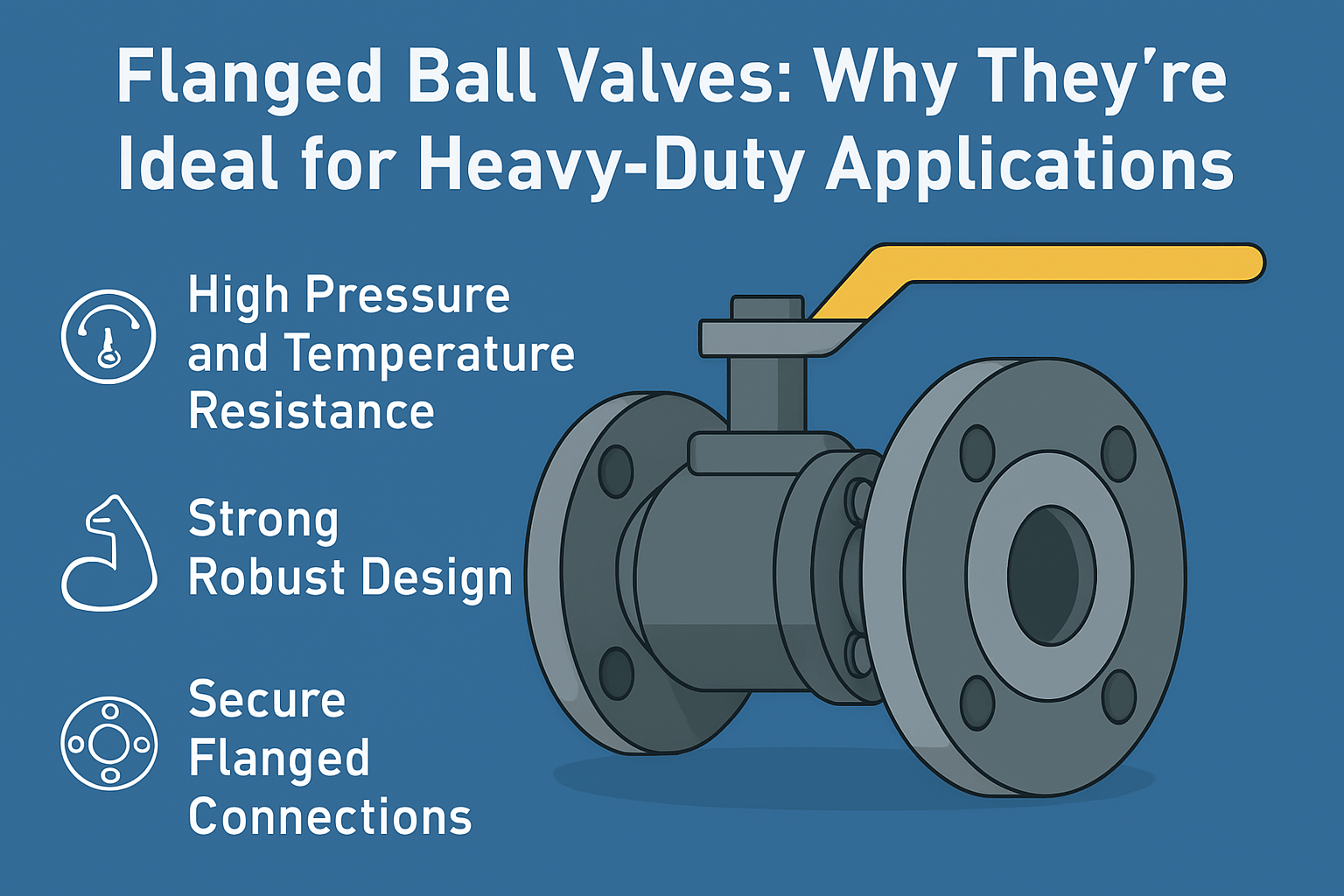

In industrial systems that handle high-pressure, intense temperatures, or corrosive materials, selecting the right valve is pivotal. The thing that can be trusted the most in such settings is the Flanged Ball Valve. These valves are famous for their longevity, easy upkeep, and secure sealing capabilities. If we talk about oil and gas, chemical plants, water treatment, or power generation, heavy-duty valves such as flanged ball valves are essential.

In this blog, we will discuss flanged ball valve benefits and define why they are perfect for heavy-duty applications. So, let’s begin.

A flanged ball is designed so that it can be quartered turned. However, it uses a spherical disc, which is commonly known as the “Ball”. This ball is used to control the flow of fluids or gases. Did you know? This creates a robust, tight seal that can handle intense pressure and high-working scenarios.

These valves are available in numerous dimensions, materials, and pressure ratings. They are mostly made with these materials:

• Stainless Steel

• Carbon Steel

• Brass

• PVC

Nonetheless, it depends on the application.

Most industrial settings have tough conditions. High pressure, elevated temperatures. High pressure, uplifted temperatures, chemical exposure, and large volumes of flow are mostly known. Not all valves can function in such setups, but flanged ball valves can. They are made in such a way that they can thrive in such setups. Let’s take a look at the main reasons why they are the number one choice.

1. Robust and Trustworthy Sealing

One of the biggest flanged ball valve benefits is that they can be sealed tightly. The credit goes to the structure of the ball and seat. However, these valves can create a perfect shut-off, even under high pressure or when dealing with dangerous liquids. The flange connection enhances this sealing by allowing the valve to be fixed properly to the pipeline. This makes it safe from leaks that could cause safety issues or downtime in heavy-duty systems.

2. Bear High Pressure and Temperature

Flanged ball valves are designed to work finely in high-pressure settings, sometimes handling more than thousands of PSI, depending on the dimensions and material. They are also able to function in extremely hot temperatures where other types of valves cannot. In fact, they would break or might deform.

3. Longevity for Long-Term Use

Longevity is a must-have quality in heavy-duty valves, including flanged ball valves. Stainless steel and high-grade carbon steel bear damage, corrosion, and cracking.

Because flanged ball valves last for a long time, they don’t need to be fixed or replaced as often. This is very helpful in saving money and ideal for those businesses that cannot afford to cease work often.

4. Easy Upkeep and Replacement

Flanged ball valves are not like other types of valves. We can easily take off and service flanged ball valves. The flanged connection allows technicians to unbolt the valve from the system. So, they don’t need to cut the pipe to execute this action.

This attribute minimizes downtime during upkeep and makes it easier to replace components or clean the valve. This action is pivotal for those industries where the criteria are cleanliness and rapid service.

5. Adaptable for Numerous Applications

Another pivotal flanged ball valve pro is their adaptability across multiple areas. They are used in:

• Oil and gas pipelines

• Chemical processing plants

• Power generation facilities

• Water treatment systems

• Marine and offshore equipment

• Food and drinks processing (with sanitary-grade designs)

No matter which industry it is in, flanged wall will always serve you with the best. Plus, they can be customized too. So, you can customize them as per your needs.

6. Strong Construction and Safety

In heavy-duty industrial applications, safety comes first. Flanged ball valves are made to meet strict industry standards such as ANSI, API, and ISO. Their sturdy and tough structure helps them resist harm from various things. Whether that is vibration, thermal expansion, or water hammer, flanged ball valves resist damage very well.

If there were any fire or failure, fire-safe structures and anti-blowout stems sometimes exist to prevent accidents. These safety attributes make flanged ball valves a dependable choice in most pivotal situations.

7. Custom Options for Special Needs

Numerous manufacturers create flanged ball valves with additional options. For example:

• Actuators enable the valve to be opened or closed from a distance. To get this job done, they use manual control, air pressure (pneumatic), electricity, or hydraulic power.

• Jacketed designs help keep the fluid inside at the correct temperature. It is useful for thick and heat-sensitive materials such as bitumen and chocolate.

• Multi-port valves can direct flow in multiple directions. It is helpful in complex piping systems.

• Anti-statis devices prevent sparks in environments where flammable gases or liquids exist.

These special attributes make flanged ball valves ideal for tough and complex systems where there are fewer chances of standard valves not working properly.

8. Cost-Effectiveness Over Time

If we compare flanged ball valves to other valves, their upfront cost is high. But its longevity and easy upkeep often result in lower overall costs. Their durability, very little need for repairs, and high performance minimize the total cost of ownership.

9. Smooth Flow Control

The function of flanged ball valves is to be opened or closed. Nonetheless, they easily release the liquids through them when they are switched on. Their full-bore design means the opening inside the valve is the same dimensions as the pipe. So, this is how there is only a little bit of pressure loss in it. This keeps the system running smoothly, especially when managing a massive flow.

In industries that operate in demanding conditions, the use of heavy-duty valves is pivotal. If we compare flanged ball valves with other standard valves, these are the best among them, especially because of their strength, trustworthiness, and flexibility. Those industries that need heavy-duty valves, flanged ball valves are optimal.

The many flanged ball valve benefits make them a perfect choice for heavy-duty applications. Whether you are working on some old project or designing a new one, flanged ball valves are the perfect choice for heavy-duty applications.

Industries must continually update their operations to achieve the best output. Not staying activ...

READ FULLThe valve system consists of various kinds of components, and actuators are one of them. When it ...

READ FULLValves need support from an electric system that can control them remotely. Not every time and pl...

READ FULL