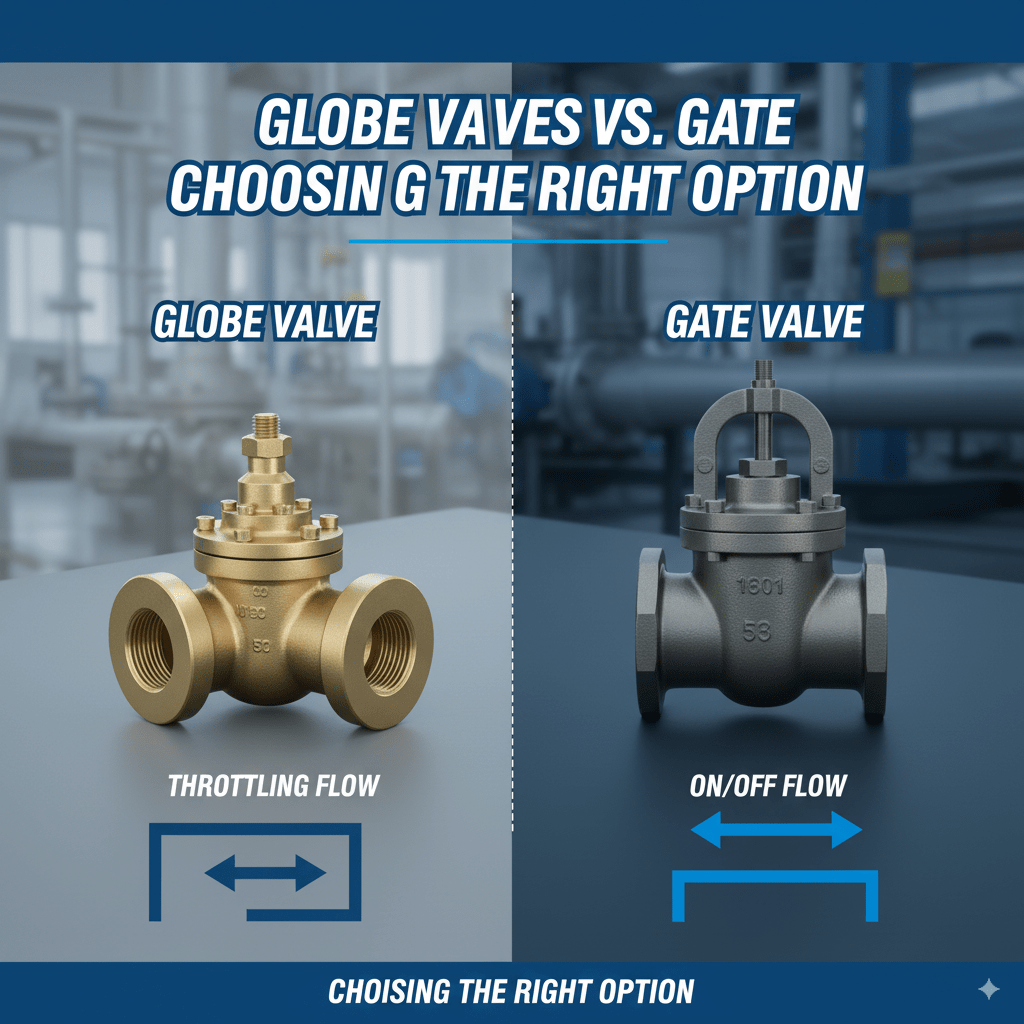

Industrial systems heavily depend on valves due to a number of reasons. There are two common types of valves: globe valves and gate valves. They look a little the same to each other. Nonetheless, their functions and attributes are different. However, what type should you prefer depends on two things: Whether you want a simple on and off function, or you want a valve that contains a throttling option. In this blog, we are going to discuss the differences between these two valves. Also, to help you make the decision which valve you should choose according to your needs. So, let’s do the gate valve and globe valve comparison. Lets begin.

The main function of globe valves is to throttle and regulate flow. The valve’s internal system contains a movable disc/plug and a stationary ring seat arranged in a spherical body. That is why it is called “Globe valve”. This structure enables the users to adjust the flow rate properly.

In those industries where controlling pressure, flow, or fluid characteristic is pivotal, globe valves are a good choice. They are widely used in different applications, including:

• Water cooling systems

• Fuel oil operations

• Feedwater regulation in power plants

Comparatively, gate valves are made for on/off flow control. They are operated by moving up in a rectangular or circular “Gate” located at the center of the valve body to let the liquid pass through it. Due to this, gate valves give minimal resistance when completely open. This creates almost an unobstructed passage. Plus, this makes them perfect for applications where full flow or full shut-off is pivotal, instead of well adjustments/ changes.

Common uses of gate valves are:

• Water distribution systems

• Oil pipelines

It includes any settings where the flow requires a complete cease or is allowed without regulation.

One of the main differences between a gate valve vs. globe valve is their operating functions: adjusting the liquid flow of fluid or a complete on/off function.

• Globe Valves for Throttling: Globe valves are excellent for throttling capabilities. Their structure allows users to open or close the valve to varying degrees, which enables fine adjustments for the flow rate and pressure. For instance, in a cooling water system, a globe valve can regulate flow to get the exact temperature balance needed.

• Gate Valves for On/Off: Gate valves, however, are not made for throttling. If we open the gate valve halfway, it can cause vibration, uneven wear, and potential harm to the gate and seat. Instead, they are made to be either completely open or completely closed. This makes them best for individual purposes, where flow control is not an issue.

The key difference between the two valves is enough to decide whether you need a throttling or a simple on/off control.

Another important factor in the gate valve vs. globe comparison is pressure drop.

• Globe Valves: Globe valves don’t have a straight fluid-flow system, which creates more resistance and a higher pressure drop. This is the reason why we declare gate valves better than these globe valves.

• Gate Valves: Gate valves create very little resistance when they are completely open. Their straight passing through structure enables liquids to flow freely through them without any hurdle. This quality makes gate valves more appropriate for:

1. Pipelines

2. Distribution networks

Upkeep and durability also differ significantly between the two valve types we are discussing here.

• Globe Valves: Globe valves have proper control over the liquids. Secondly, they are used more frequently. It makes them get damaged easily and quickly. The globe valves demand daily or frequent upkeep to keep running, especially when they come in contact with chemical fluids. Moreover, the latest designs often include renewable seats, which makes it easy to maintain them.

• Gate Valves: Gate valves last longer when used properly (for example, when they are completely open or completely shut). Plus, because they are not made for frequent throttling, they face less damage if used strictly as isolation valves.

When selecting either of these valves, we must also consider their prices.

• Globe Valves: Globe valves are normally very costly. The reason is their complicated structure and manufacturing processes. Plus, they are heavier and bulkier than gate valves. This can be a con in space-constrained fittings.

• Gate Valves: Gate valves are comparatively lightweight and cheaper than globe valves. This is the reason why many people choose them. Plus, they have a simple design and are available in large sizes.

Ease of operation is another pivotal thing to consider, especially in systems that need frequent adjustments.

• Globe Valves: Globe valves need more torque to operate because of their flow design and pressure drop. However, they give flawless and proper adjustments, advantageous for operators needing fine control.

• Gate Valves: Gate valves are easy to operate if they are used the way they are supposed to be. Opening and shutting takes longer because of the gate’s travel distance. But once fully actuated, they give a secure seal, which requires minimal operator effort.

If you want to understand the gate valve vs. globe comparison better, take a look at these real-world applications:

• Globe Valves Applications: These are common in situations where regulating flow is pivotal. Examples are:

1. Feedwater regulation in power plants

2. Chemical dosing

3. Cooling water circulation

• Gate Valve Applications: These are preferred in systems needing individuality. Some examples are:

1. Main water pipelines

2. Oil and gas transportation lines

3. Fire protection systems where the valve has to stay completely open until it is shut off fully.

Ultimately, which valve is correct for you depends on the nature of your required work/task:

• If you wish to have accurate flow control, go with a globe valve because it’s beneficial for you.

• If you need full individuality with minimal resistance, a gate valve is the optimal choice.

By doing a globe valve comparison, we can help you make the right decision regarding which valve to select.

When we talk about valves, both globe valves and gate valves serve pivotal but different roles. The main function of a globe valve is to throttle and regulate flow. However, it requires a lot of upkeep as well. Gate valves, on the other hand, are made to perform just the opposite of globe valves. While they provide minimal resistance when we completely open them. Also, they are durable if used in the right manner.

When you are making the decision, give importance to factors such as:

• Throttling vs. on/off capabilities

• Pressure drop

• Maintenance

• Cost

• Application needs

We are sure that you have understood the differences between gate valves and globe valves. So now, you can choose the correct valve to optimize performance, increase equipment lifespan, and ensure system performance.

Industries must continually update their operations to achieve the best output. Not staying activ...

READ FULLThe valve system consists of various kinds of components, and actuators are one of them. When it ...

READ FULLValves need support from an electric system that can control them remotely. Not every time and pl...

READ FULL