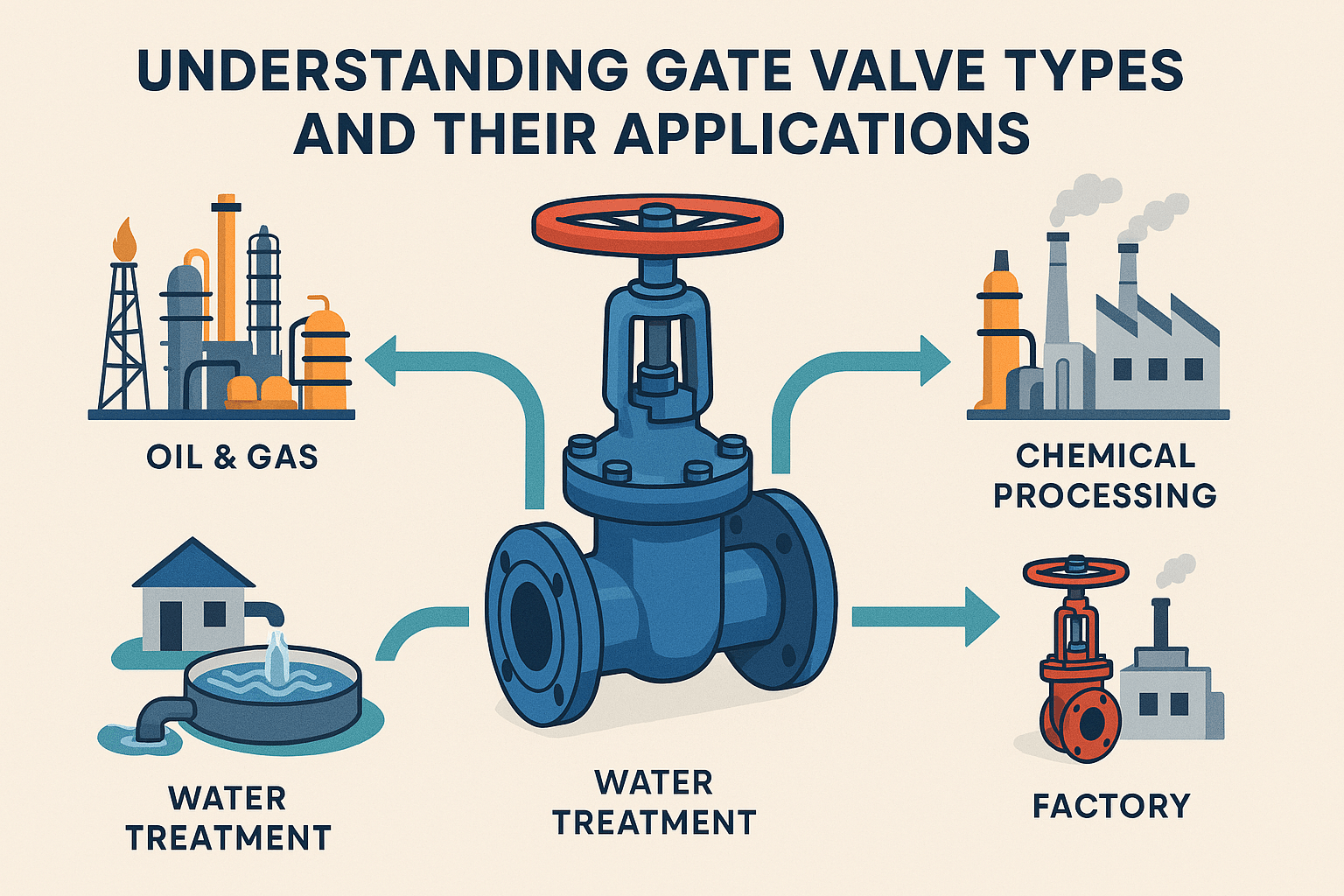

Industries have to install the types of valves that can meet their requirements and compatibility precisely. Gate valves are among the most efficient types in various sectors, contributing to efficient liquid and gas flow systems. When we discuss gate valve applications, there are many. Their versatility, efficiency, and variety make them highly compatible for industrial operations. To clarify, the detailed version is provided below.

Industries must install various types of valves, including gate valves. However, they also have subtypes, and each type shows specific advantages. Industries utilize them to control the flow of liquids and gases, ensuring stable results. Find out about these gate valve types that contribute to industrial success.

The most common and widely used type is the wedge gate valve. It has a wedge-shaped disk for the opening and closing system. When operators rotate the handle at its top, the wedge disk inside the valve moves up or down. These closing and opening operations take place slowly because there is no fast shutoff mechanism. You can find rigid and flexible wedge options in it, which are selected based on pressure and temperature rates.

There is also a parallel slide gate valve, which features two parallel disks inside. These disks move up and down together to stop and allow the flow of liquids and gases. This type is suitable for large systems where a massive flow needs to be controlled. It provides more stable results than most types.

One of the gate valve types has a slab inside. That slab has a hole parallel to the pipe. When it is opened, the hole gets aligned with the pipe’s diameter. When it is closed, the hole goes down in the extra portion at the bottom of the valve. It is vertically larger than other valves because of this slab system.

Then we have a knife-like disk, which is ideal for slurries and thick liquids. Some applications require gate valves that can easily shut off and on without having a blockage. This is why the knife gate valve is an efficient type for this scenario. It is one of the gate valve types that can completely disconnect the flow of thick liquids of all kinds without showing resistance.

This type of valve features a stem that moves up and down in conjunction with the gate inside the valve. This is why it is suitable for places where vertical space is available. They are compact in the horizontal dimension but longer in the vertical direction. When it comes to open-area installations, these valves give fine support.

Then one of the second gate valve types comes, which is a non-rising stem gate valve. In areas where vertical space is limited or scarce, these valves are the best choice. The stem remains stationary in a constant position, and the gate moves vertically. Since the stem remains stationary, it is hard to identify if it is open or closed. Therefore, it is the best choice for underground installations where there is insufficient space for the stem to rise.

Some types are different in terms of bonnet structure. Screwed bonnet gate valve is one of them, whose bonnet is installed on the body with a screw. It is suitable for low-pressure flow where the risk of leakage and explosion is very low. It is also one of the common types in the industry.

A more secure type than the above one is the bolted bonnet gate valve. It is a tighter option, where the bolts are used to connect the bonnet to the body. They create higher pressure on the disk to hold the liquid and gas.

When there is a risk of leakage, a welded bonnet gate valve proves to be a better choice. This one has a welded bonnet that maintains high pressure and prevents leakage. Industries that deal in high-pressure flow use this type.

When it comes to extremely high-pressure flow, this type is the best choice. A pressure seal bonnet gate valve has a one-piece structure, where the valve and the bonnet cannot be separated at all. That means the seamless structure helps the valves withstand high temperatures and pressure without exploding or leaking.

Many industries utilize them due to the user-friendly and stable shutoff system that these gate valves provide. Chemical plants, petrochemical pipelines, pharmaceutical production facilities, and numerous other industrial plants utilize gate valves for safe control operations. Here are some main functions of them that make them substantial in the industry.

They allow flow in two ways, which makes them suitable for multiple controls. Mixing operations require these types of valves for optimal results. Industries install them in valve applications where various kinds of chemicals need to be reacted. Also, the pressure drop is very low in them.

Unlike a fast-shutoff system, these gate valves provide a gradual shutoff. The wheel at the top of them takes time to rotate and move the disk inside the valve, which prevents water hammering. The lining and the valve’s internal components face less risk of wear and tear because of it.

When industries need to isolate specific lines, they require valves that can facilitate such operations. Fortunately, gate valves provide this function through their two-way flow system. They can shut one side to isolate the other line. It helps with maintenance work mostly.

However, these valves are not suitable for throttling. If you want to install them for throttling applications, that will be a wrong move. They will either completely open or completely shut off. There is no in-between for throttling.

Now, you know everything about gate valve types and applications. We described everything in the simplest way possible. Industries rely on gate valves because of their gradual shutoff system, which prevents water hammering. Besides, their compact shape makes them an ideal choice for low spaces. Installing them can provide a straightforward solution for controlling fluids and gases in various industries.

Industries must continually update their operations to achieve the best output. Not staying activ...

READ FULLThe valve system consists of various kinds of components, and actuators are one of them. When it ...

READ FULLValves need support from an electric system that can control them remotely. Not every time and pl...

READ FULL