Butterfly valves are pivotal where there are numerous liquid control systems. These valves are famous for their simplicity, small size, and fast functioning. They are hugely used in industries these days. Their qualities are:

• Water treatment

• HVAC

• Pharmaceuticals

• Food processing

This blog highlights the basics of butterfly valve design and their common applications. Are you an engineer, a technician, or a buying expert? Getting to know butterfly valves can help you make intelligent choices for your piping and flow control requirements.

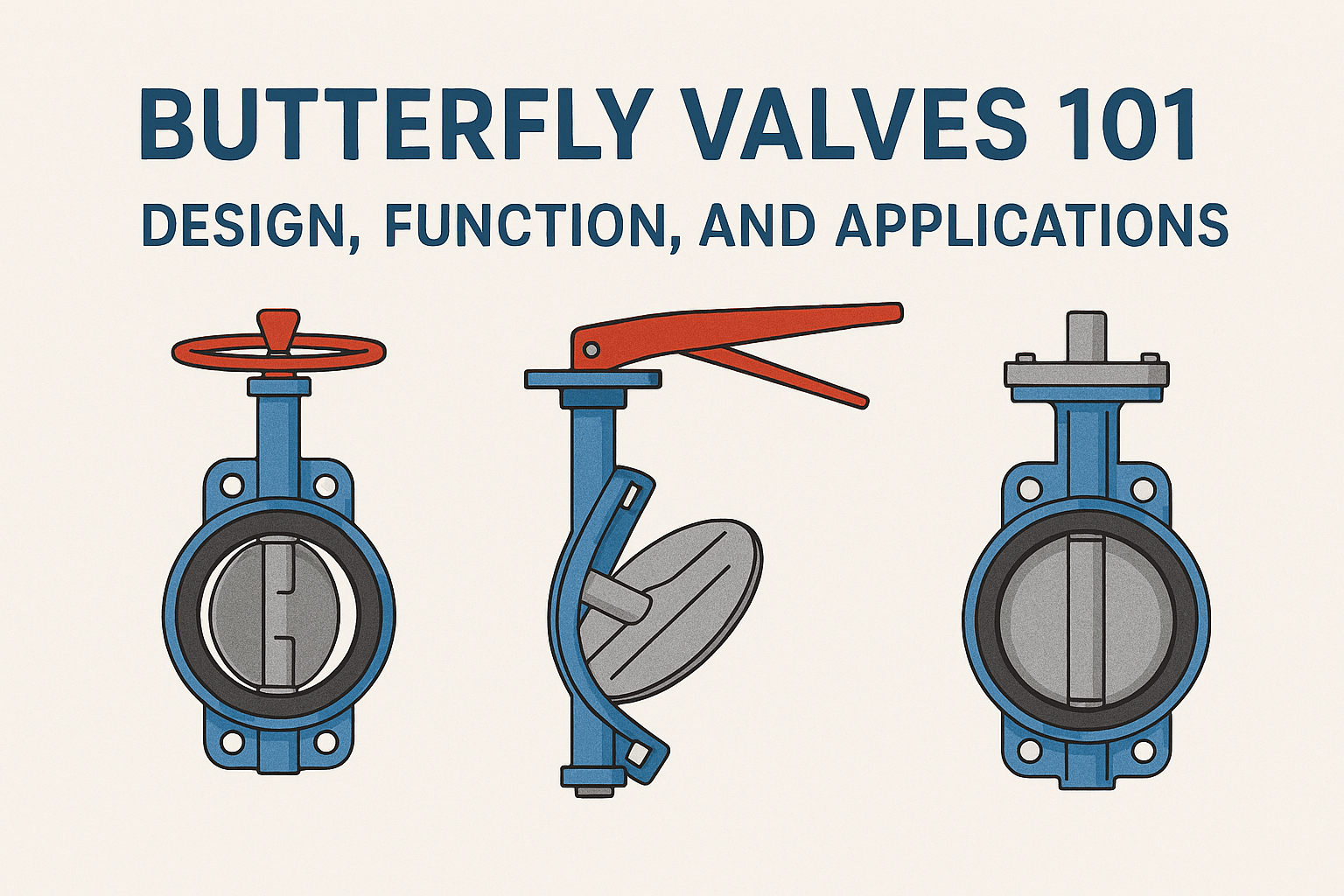

A butterfly valve is a valve that turns quarterly. Furthermore, it uses a round disc or plate to pass fluids through it. When it is completely closed, the disc ceases to pass through the passageway. Just like this, when it is completely open, the disc rotates to enable unrestricted flow.

The simple design of a butterfly valve is something that makes it special. The butterfly valve is totally different from a globe or gate valve. These valves have complicated motions and more than one internal part. A butterfly valve’s disc rotates directly on a central shaft. This enables quick opening and closing – making it a go-to solution where flow control and space efficiency are essential.

Here is how a butterfly valve functions:

1. Closed Position: The disc sits at a straight angle to the flow path, closing the flow fully.

2. Open Position: The disc changes its position. It rotates quarterly (which is 90 degrees) to align with the flow path, allowing full flow.

3. Mid Position (Half Opened, Half Closed): The valve can also be set to partially open to control flow volume.

Butterfly valves can be opened and closed manually (with the help of a handle, gear, or lever). Or it can be done automatically (with electric, pneumatic, or hydraulic actuators), depending on the system's needs.

Understanding butterfly valve design is pivotal to buying a new one. These valves are made up of numerous pivotal parts that work with each other.

1. Valve Body

The valve body makes up the external body of the butterfly valve and connects it to the pipeline. It is available in different connection types. They include wafer, lug, and flanged designs. The connection type determines how the valve integrates with existing piping systems. Also, it is chosen based on pressure requirements and easy upkeep.

2. Disc

The disc is one of the main components of a butterfly valve. This disc changes its angle to stop or enable the flow of liquid. The material of the disc varies according to the liquid type and operating pressure. Common materials include stainless steel, ductile iron, and PVC, each selected for specific valve applications.

3. Stem/Shaft

The shaft joins the disc to the handle or actuator. It is responsible for rotating the disc during operation. It all depends on the valve type, whether the stem has to be centered or offset. It affects how the valve functions and seals.

4. Seat

The seat is the seal inside which keeps the liquid stopped properly when the valve is closed. Seats are made up of soft materials. However, the type of seat varies according to the kind of liquid flowing through the system.

5. Actuator

The actuator is the part used to control the valve. It can be manual. However, it uses a lever or gear, or is automated through electric, pneumatic, or hydraulic systems. The actuator selection relies on whether remote control or automation is required in the application.

As a summary, butterfly valve design focuses on minimizing pressure drop while providing efficient flow control and shut-off. Its compact and efficient design also makes it appropriate to install in a small space.

There are numerous types of butterfly valves. Each of them is made for particular pressure conditions, flow attributes, and valve applications. Let’s understand these types so that you can buy the correct one.

This is the most common type of valve that is widely used. In a concentric design, the stem is put in the middle of the disc, which itself is centered within the pipe bore. This configuration means the disc changes its direction within a soft elastomer seat, making it ideal for low-pressure systems. Concentric butterfly valves are generally used for basic shut-off or light throttling. Common applications include water supply, wastewater treatment, HVAC systems, and chemical or food-grade processes – especially when appropriate seat materials are chosen. This butterfly valve design is economical and performs well in simple, low-pressure areas.

Double eccentric valves contain a shaft offset behind the disc and to the side. This reduces wear and friction in the middle of the disc and the seat. This enables the disc to “cam” into its position during operation. As a result, the valve manages higher pressure and flow rates compared to the concentric type. These valves are normally seen in power generation, chemical processing, and high-pressure water systems. Their butterfly valve design provides better longevity and sealing performance in demanding conditions.

The triple offset butterfly valve contains three different offsets. One from the centerline of the disc, the other from the centerline of the body, and a third that introduces an angular offset. This unique configuration makes sure that there is no friction in the middle of the disc and the seat during operation. With a metal-to-metal seat, these valves are perfect for high-pressure and high-temperature systems. Applications include steam lines, petrochemical plants, and cryogenic services.

These types define how the butterfly valve is connected to the pipes, without the changes in the disc or stem.

Water-style butterfly valves are placed in the middle of the two pipe flanges and held in position with the help of bolts. They are small and budget-friendly. This quality makes them perfect for areas with limited space.

Lug-style butterfly valves come with threaded holes, also known as lugs, on both sides. These enable the valve to be bolted directly to the pipe flanges. This setup is useful. Why? Because you are able to eliminate one side of the piping system without needing to shut down the whole system.

Many industrialists prefer butterfly valves over other valves for some genuine and logical reasons:

• Their size is compact. So that you can install them in congested places.

• They have a lightweight design. So that you can carry them anywhere that you want.

• These valves have quick-turning ability, which saves time.

• They are adaptable. In simple words, they can handle a range of media.

• They are cost-effective for both the initial cost and upkeep. It is because they have fewer moving components and a simple design.

Butterfly valves are used in numerous industries due to their versatility, sealing capacity, and low upkeep requirements. Below are a few of the most common valve applications:

Butterfly valves are commonly used in water systems to cease or control the flow of water. They also help manage the movement of sludge or sediment in pipes. These valves are famous for being rust-free.

Butterfly valves play a pivotal role in the oil and gas sector. Pivotal applications are pipelines, storage systems, and fuel transfer operations. They are also used in situations when a quick shut-off is required.

In HVAC systems, butterfly valves are used for controlling extremely cold water, air balancing, and managing cooling tower distribution.

Butterfly valves are used in systems that clean equipment without removing it. They are also used in pipes that transfer fluids. Also, they are used in processes that measure and transfer specific amounts of liquids. Special food-grade butterfly valves are made with clean, safe materials to prevent contamination. They help keep the process hygienic while allowing smooth and efficient control of liquid flow.

Pharmaceutical plants require hygienic environments. They also need perfect control of fluids and gases. Therefore, butterfly valves are often used in these environments.

Butterfly valves need very little care and upkeep due to their simplicity. Nonetheless, regular inspection of the seat, disc, and stem can result in better functioning.

Butterfly valves are an adaptable and cost-effective solution for liquid control over a wide range of industries. From the simple concentric type used in water systems to the advanced triple eccentric designs for demanding industrial processes, there is a butterfly valve design to suit every application. The credit goes to their reliability, ease of use, and broad valve applications. Butterfly valves are the number one choice of all the designers and operators.

Industries must continually update their operations to achieve the best output. Not staying activ...

READ FULLThe valve system consists of various kinds of components, and actuators are one of them. When it ...

READ FULLValves need support from an electric system that can control them remotely. Not every time and pl...

READ FULL